800w 24000rpm ER11 65mm 110V water cooling spinel motor&1.5kw 1phase 110V VFD inverter CNC kits

- Model: 65 800w 110v

- Shipping Weight: 8Kg

- In Stock:50

0 reviews

0 reviews

800w 24000rpm ER11 65mm 110V water cooling spindle motor&1.5kw 1phase 110V VFD inverter CNC kits

package included:

1pcs 800w 24000rpm ER11 65mm 110V water cooling spindle motor

1pc 1.5kw 1phase 110V VFD inverter

Description:

The spindle motor:

1HP 0.8kw 24000RPM ER11 water cooling Woodworking AC Spindle motor 65mm 2 bearings 110VAC 10A 400hz CNC Router

1, Spindle Specification

|

Brand |

HY |

|

Spindle Model |

65 800w 110v |

|

Dimension |

65mm*158mm |

|

Speed |

24000rpm |

|

Rated Power |

0.8kW |

|

Voltage |

AC110V |

|

Current |

10A |

|

Frequency |

400HZ |

|

Bearings |

1*7002, 1*7000 |

|

Collet |

ER11(Random send a collet as free) |

|

Cooling Type |

Water cooling |

|

Lubricate |

Grease |

|

Plug connection: |

Plug in 1234 pin, 1-U, 2-V, 3-W, 4-GND or not connected. if 123 not connected correctly, the motor will reverse. Swap any two wires can be OK. |

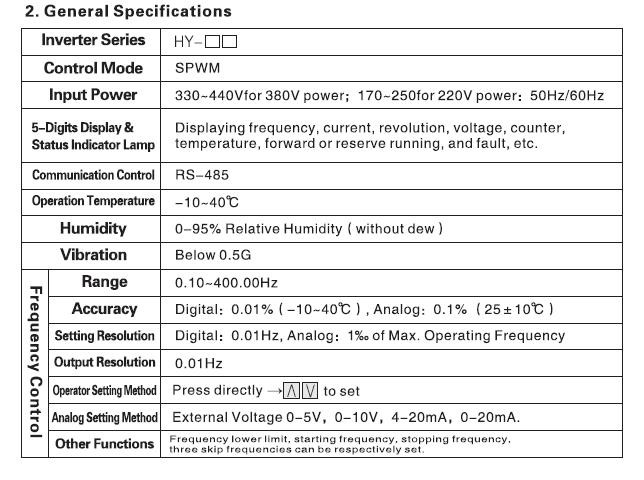

The VFD inverter:

2HP 1.5KW 400HZ VFD Inverter Frequency converter single phase 110V input 3phase 110V output 12A for Engraving spindle motor

Instructions

|

1 |

The electric spindle must be matched with the frequency converter. Frequency converter selection must be matched with the power, voltage, current, frequency and other parameters of the electric spindle. The use of electric spindle must first set the benchmark frequency of the inverter. The reference frequency of the frequency converter is set according to the highest frequency of the electric spindle. Inverter reference frequency conversion factory default settings 50hz. If the base frequency of the inverter is not set before the spindle motor is used, the spindle motor can be burnt down. |

|

2 |

Before use, you should use the hand to turn the spindle motor, and confirm that it can rotate smoothly. |

|

3 |

When in use, you must first connect to the spindle motor cooling water pipes, water pipes to ensure. Water flow is not less than 5L/min |

|

4 |

If the electric spindle needs to be replaced with a new bearing, |

4, The common faults and their elimination methods

|

The Fault |

The Reason |

The Solution |

|

The electric spindle does not run after start |

1.No output or wrong setting for the inverter |

check the output and setting of the inverter |

|

2.Plug not connected |

check the plug and connection cable |

|

|

3.the cable not connected |

||

|

4.The stator winding burned |

change the stator |

|

|

Few seconds after start,the spindle stop running |

1.water inlet |

Drying stator |

|

2.High temperature induced wire insulation damage |

change the stator |

|

|

3.Lack of phase operation caused over current protection |

check the cable connecting of the spindle motor |

|

|

4.Start-up time is too short |

Extended acceleration time |

|

|

Motor smoke or shell hair hot |

1.The inverter output voltage, frequency is not match with the spindle motor |

check the setting of the inverter |

|

2.the frequency of the inverter is not set correctly |

reset the frequency of the inverter |

|

|

3.Air duct blockage |

check the air duct |

|

|

Nut loosening when start |

Rotation direction error |

recorrect the rotation according the instruction on spindle |

|

Noise and vibration |

1,bearing damaged |

change bearings |

|

2.Parts precision damage affect dynamic balance |

Check dynamic balance |

|

|

3.Large spindle runout |

change spindle |

|

|

Nut loosening when stop |

Down time is too short |

Prolonged deceleration time |

There are currently no product reviews.