2 phase Closed loop Step servo driver for NEMA34 NEMA42 motor 60V-80VAC 6A JMC 2HSS86H

- Model: 2HSS86H

- Shipping Weight: 1Kg

- In Stock:98

- Manufactured by: JMC

0 reviews

0 reviews

2 phase Closed loop Step servo driver for NEMA34 NEMA42 motor 60V-80VAC 6A JMC 2HSS86H

- Full closed loop control

- Motor with standard 1000 line encoder

- It save energy and achieve nearly 100% output torque .

- Micro step setting range is 2-256

- High speed response , High speed

- Optical isolation fault alarm output interface ALM

- Current loop bandwidth: (-3dB) 2KHz (typical value)

- Speed loop bandwidth: 500Hz (typical value)

- Position loop bandwidth: 200Hz (typical value)

- RS232 serial communication available to download or change the parameters

- Optical isolation fault alarm output interface ALM

- Over current, I2T, over voltage, under voltage,temperature, speeding, over-differential protection

- Alarm clear input ENA

Typical applications:

CNC machine ,cutting machine ,engraving machine

Introduction

2HSS86H two-phase hybrid stepper servo drive system integrated servo control technology into the digital step driver. It adopts typical tricyclic control method which include current loop,speed loop and position loop.This product has the advantage of both step and servo system, and it’s a highly cost effective motion control products.

Electrical Specifications

|

Parameters |

Min |

Typical |

Max |

Unit |

|

Supply voltage |

30V |

60V |

75V |

VAC |

|

Output Current (Peak) |

- |

- |

8.0 |

Amps |

|

Logic Input Current |

- |

10 |

- |

mA |

|

Pulse input frequency |

- |

- |

200 |

KHz |

|

Low Level Time |

2.5 |

- |

- |

µsec |

Environment

|

Cooling |

Natural Cooling or Forced Convection |

|

|

Environment |

Storage Space |

Avoid dust, oil frost and corrosive gases |

|

Ambient Temperature |

-20°C - +80°C |

|

|

Humidity |

<80%RH |

|

|

Vibration |

5.9m/s² Max |

|

|

Storage Temp. |

-20°C - +80°C |

|

|

Weight |

Approx. 580 gram |

|

Microstep Resolution Setting

|

SW3 |

SW4 |

SW5 |

SW6 |

|

|

Default |

ON |

ON |

ON |

ON |

|

800 |

OFF |

ON |

ON |

ON |

|

1600 |

ON |

OFF |

ON |

ON |

|

3200 |

OFF |

OFF |

ON |

ON |

|

6400 |

ON |

ON |

OFF |

ON |

|

12800 |

OFF |

ON |

OFF |

ON |

|

25600 |

ON |

OFF |

OFF |

ON |

|

51200 |

OFF |

OFF |

OFF |

ON |

|

1000 |

ON |

ON |

ON |

OFF |

|

2000 |

OFF |

ON |

ON |

OFF |

|

4000 |

ON |

OFF |

ON |

OFF |

|

5000 |

OFF |

OFF |

ON |

OFF |

|

8000 |

ON |

ON |

OFF |

OFF |

|

10000 |

OFF |

ON |

OFF |

OFF |

|

20000 |

ON |

OFF |

OFF |

OFF |

|

40000 |

OFF |

OFF |

OFF |

OFF |

Input edge settings

* SW1 : Dialing Switch checking Input edge settings .

* OFF=Rising edge effective , ON= falling edge effective

Logical direction setting

* SW2:When dialing switch SW2 switches ON or OFF , it can change the present running direction of motor

* OFF=CCW , ON=CW

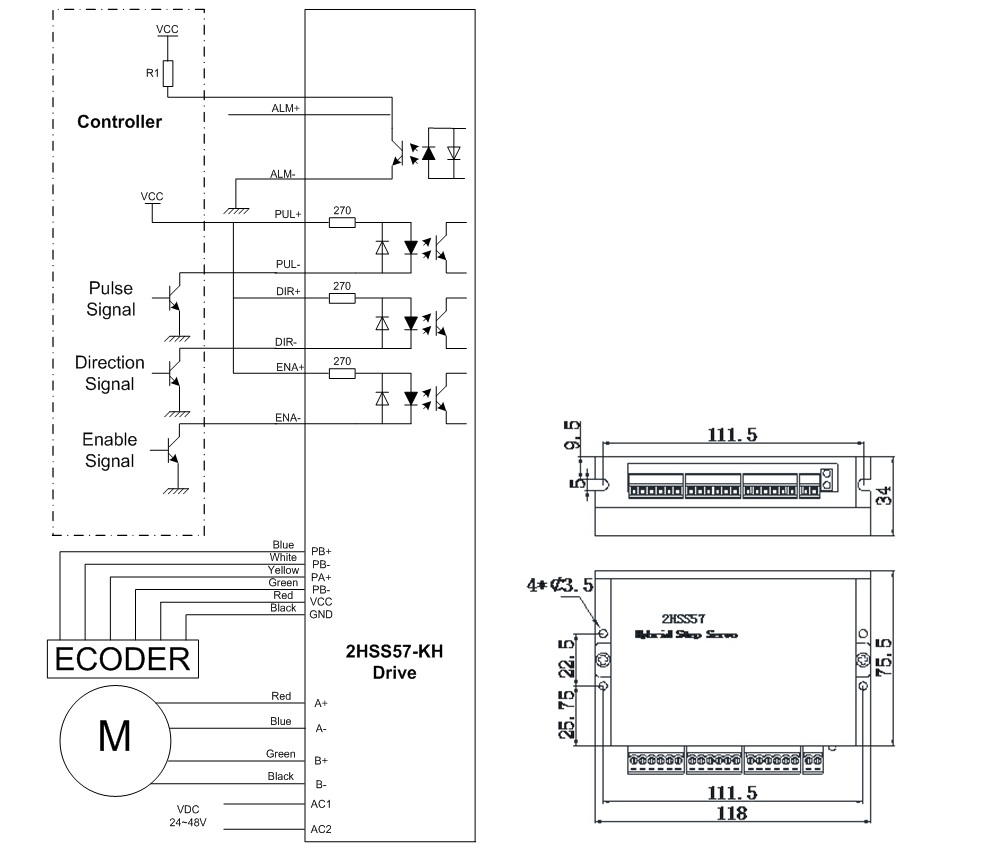

ALM and PEND signal output ports

|

Port |

Symbol |

Name |

Remark |

|

1 |

PEND+ |

In position signal output + |

|

|

2 |

PEND- |

In position signal output - |

|

|

3 |

ALM+ |

Alarm output + |

|

|

4 |

ALM- |

Alarm output - |

Control signal input port

|

Port |

Symbol |

Name |

Remark |

|

1 |

PLS+ |

Pulse signal + |

Compatible with 5V or 24V |

|

2 |

PLS- |

Pulse signal - |

|

|

3 |

DIR+ |

Direction signal+ |

Compatible with 5V or 24V |

|

4 |

DIR- |

Direction signal- |

|

|

5 |

ENA+ |

Enable signal + |

Compatible with 5V or 24V |

|

6 |

ENA- |

Enable signal - |

Power Interface Ports

|

Port |

Identification |

Symbol |

Name |

Remark |

|

1 |

Motor Phase Wire Input Ports |

A+ |

Phase A+(Red) |

Motor Phase A |

|

2 |

A- |

Phase A- (Blue) |

||

|

3 |

B+ |

Phase B+(Green) |

Motor Phase B |

|

|

4 |

B- |

Phase B-(Black) |

||

|

5 |

Power Input Ports |

VCC |

Input Power + |

AC24V-70V DC30V-100V |

|

6 |

GND |

Input Power- |

Encoder Feedback Signal Input Ports

|

Port |

Symbol |

Name |

Wiring color |

|

1 |

PB+ |

Encoder phase B + |

Blue |

|

2 |

PB- |

Encoder phase B - |

White |

|

3 |

PA+ |

Encoder phase A + |

Yellow |

|

4 |

PA- |

Encoder phase A - |

Green |

|

5 |

VCC |

Input power |

Red |

|

6 |

GND |

Input power ground |

Black |

There are currently no product reviews.