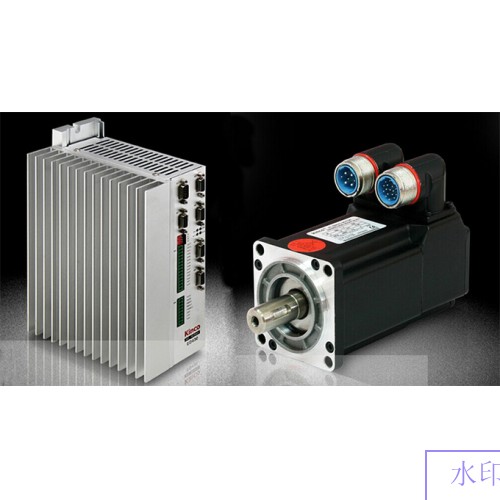

SMH-110D-0105-20AAK-4LKC+ED430-0105-PA-K-000 AC220V 1.05KW 5.9A 5NM 2Krpm 110mm AC Servo Motor Drive kits with 3M cable

- Shipping Weight: 12Kg

- In Stock:10

- Manufactured by: Kinco

0 reviews

0 reviews

Motor + Drive: SMH-110D-0105-20AAK-4LKC+ED430-0105-PA-K-000

1 Motor Specifications

|

Servo Motor series |

Medium inertia, flange size 110mm |

|

|

Model |

SMH110D-0105-20AAK-4LKC |

|

|

DC link voltage UDC |

300 |

|

|

Continuous |

Rated power PN (W) |

1050 |

|

Rated torque TN (Nm) |

5 |

|

|

Rated speed nN (rpm) |

2000 |

|

|

Rated current IN (A) |

5.9 |

|

|

Maximum torque Tm (Nm) |

15 |

|

|

Maximum current Im (A) |

17.7 |

|

|

Standstill torque TS (Nm) |

5.5 |

|

|

Standstill current IS (A) |

6.49 |

|

|

Resistance line-line RL (ohm) |

1.03 |

|

|

Inductance line-line LL (mH) |

7.8 |

|

|

Electrical time constant τe (ms) |

7.57 |

|

|

Mechanical time constant τm (ms) |

1.55 |

|

|

Reverse voltage constant Ke (V/krpm) |

55 |

|

|

Torque constant Kt (Nm/A) |

0.91 |

|

|

Rotor moment of inertia Jm (Kg·cm²) |

7.2 |

|

|

Pole pair number |

4 |

|

|

Maximum voltage rising du/dt (KV/μs) |

8 |

|

|

Insulation class |

F |

|

|

Maximum radial force F (N) |

630 |

|

|

Maximum axial force F (N) |

315 |

|

|

Weight G(Kg) |

7.2 |

|

|

Length of motor L(mm) |

185 |

|

|

Position feedback device |

Incremental encoder 2500ppr |

|

|

Cooling method |

Totally enclosed, non-ventilated |

|

|

Protection level |

IP65 for body, shaft sealing IP54 |

|

|

Environmental |

Temperature |

-20centigrade degree~40centigrade degree |

|

Humidity |

Below 90% RH (No condensing) |

|

|

Ambient enviroment |

Away from active gas, combustible gas, oil drops and dust |

|

|

Altitude |

Maximum altitude 4000m, Rated power at 1000m or below, Above 1000m: Decreasing 1.5% per 100m rise |

|

2 Drive Specifications

|

Model |

ED430-0105-PA-K-000 |

|

Main Supply Voltage |

Single-Phase AC220V±15% |

|

Rated Power Frequency |

50Hz~60Hz |

|

Control Power Supply |

DC24±10% , 2A |

|

Digital Signal Input |

DC24±10%, 10mA |

|

Digital Signal Output |

DC24±10%, 0.5A |

|

Analog Signal Input |

-10V~+10V |

|

Rated Output Power(KW) |

1.05 |

|

Energy-Consumed Braking |

If the system generates an over-voltage alarm when it starts or stops sharply, add an external braking resistor to absorb the feedback energy of the motor, the minimum resistance for ED430 Series is 27W |

|

Energy-Consumed Braking Voltage |

DC385±5V |

|

Over-Voltage Alarm Voltage |

DC400±5V |

|

Under-Voltage Alarm Voltage |

DC210±5V |

|

Dimensions mm (H×W×D) |

265X165X97 |

|

Weight |

3Kg |

|

Operating Temperature |

0~40centigrade degree |

|

Storage Temperature |

-10~70centigrade degree |

|

Humidity |

5~85% |

|

Contamination Level |

2 |

|

Protection Level |

IP20 |

|

Installation Environment |

Installed in a Dust-Free, Dry, and Lockable Environment (in a Electrical Cabinet, for Example) |

|

Installation Mode |

Vertical Installation |

|

Installation Altitude |

No Power Limit Under 1000m |

|

Pressure |

86~106Kpa |

|

Internal Programmable |

An Internal Space of 16.5 KB is Provided for 256 Sequences, Which can Save a Controller on Some Occasions |

|

External I/O |

3 External Digital Outputs (24V,0.5A),the Target Position to Output or Alarm Output Function can be Implemented by Internal Programming |

|

8 External Digital Inputs, Supporting Internal Sequence Calling Via the Input Interface and Positioning Function |

|

|

(Input Delay: About 1 ms; Input Current: About 4 mA) |

|

|

Analog Input |

One Differential Analog Input, Implementing Control Over Motor Speed and Position by Analog Input; Input Voltage Range ± 10V, Input Delay: About 0.1 ms |

|

Analog Output |

Two Independent Analog Outputs, Capable of Monitoring the Change of Internal Object |

|

Comparator |

Four Internal Comparators, With the Comparison Results to be Used to Trigger Program Sequences |

|

Timer |

Supporting the Function of Triggering Sequences by Timer or Events |

|

Counter |

Four Groups of Internal Counters, Which can be Set to Trigger Sequences |

|

Calculator |

An Internal Calculator can be Used for Data Duplication, Addition, Subtraction, Multiplication, and Division, and Logic Operation |

|

Internal Oscilloscope |

The ECO2WIN Software Enables a User to Monitor Operation Parameters Such as Speed, Position and Current on a PC |

|

Encoder Signal Output Function |

In a Master/Slave Control Mode, the Motor Encoder Signal or Master Encoder Signal can be the Input for the Slave Signal Encoder, With a Maximum Output Frequency of 2 MHz |

|

Master Encoder Signal Input Function |

Programmable to be Pulse/Direction Signal Control, CW/CCWW Control, Electronic Gear or electronic cam control (5V signal), with a maximum input frequency of 2 MHz |

|

Feedback Signal |

Incremental A, B, Z , /A, /B, /Z Signal |

|

RS232 |

9.6K Baud Rate, Supporting a Maximum of 15 Sites, and Supporting Direct Communication with a PC with the ECO2WIN Software, or Direct Communication with an eView Touch Screen or Text |

|

PROFIBUS DP |

Maximum Baud Rate of 12M, and Supporting a Maximum of 127 Sites |

There are currently no product reviews.